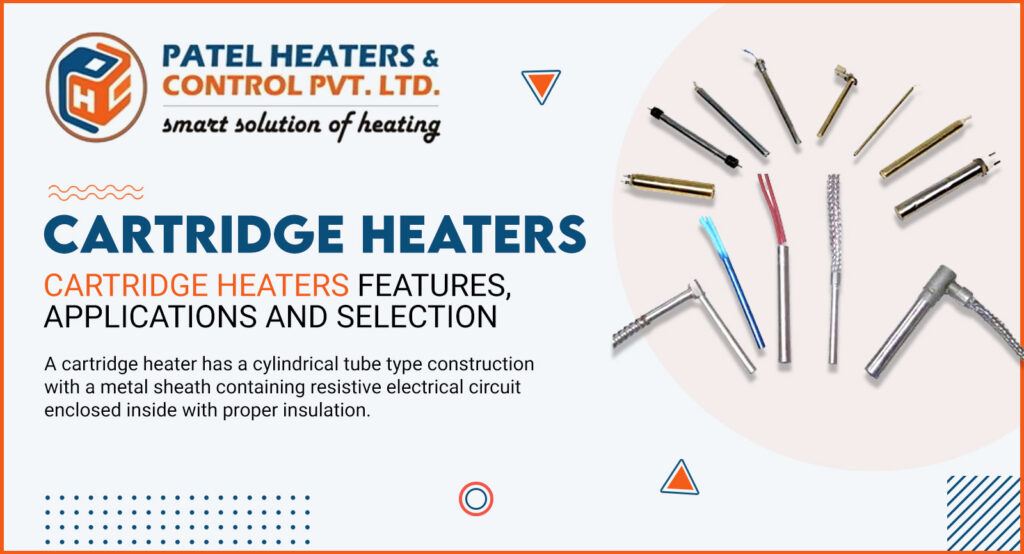

A cartridge heater has a cylindrical tube type construction with a metal sheath containing resistive electrical circuit enclosed inside with proper insulation. It is a heating element used in various industrial applications. This type of heater is designed in such a way that the diameter has a standard dimension that can slide into holes of metric drill sizes commonly ranging from 4mm to 20mm. The length may vary from less than an inch to a few feet.

Generally these heaters are used to heat up solids by the phenomenon of conduction. The heater is made to slide into the hole drilled into a mold containing the solid. Uniform heating is a desirable feature of these heaters.

How to select a cartridge heater

Cartridge heaters are commonly used in industrial processes like mold dyeing, sealing bars, platen heating and similar processes. If you are looking for such a heater that suits your requirements, here are a few important things that you should consider:

- The nature of material to be heated

- The mass of the material to be heated

- The maximum watt density for the material

- The initial temperature

- The final temperature to be attained

- Target time in which final temperature is to be attained

- Available voltage and phase

- These are designed with internal thermo-couples

- These are available with lead wire options

- Provided with Flanges and Fittings

- Great performance in terms of uniformity in heating

- Durability

- Available in a number of configurations and constructions as per specific application

- Corresponds to international performance standards

- For packaging

- Plastic processing plants

- Heating gases and liquids

- Hot runner mold

- Labeling machineries

- Hot Stamping

- Dies and molds

- Food processing machinery

- Shoe manufacturing machines

- And many more…

Patel Heaters

Patel HeatersPatel Heaters and Control has immense expertise in the manufacturing of Industrial heaters and heating elements. We have been providing heating solutions to our clients since 1982.